How to Choose the Right Solid State Phase Converter for Your Business Needs

In today's rapidly evolving industrial landscape, the efficient operation of machinery is paramount for business success. According to a report by the National Electrical Manufacturers Association, industrial power consumption in the U.S. is projected to rise by 2.3% annually, driving the demand for reliable power conversion solutions. Among these solutions, the solid state phase converter stands out due to its ability to provide consistent three-phase power from single-phase sources, a feature critical to many manufacturing applications.

As businesses increasingly aim to enhance their productivity while minimizing downtime, choosing the right solid state phase converter is essential. With various models and specifications available, understanding their functionalities and applications becomes crucial for meeting specific operational needs. This guide will explore key factors to consider when selecting a solid state phase converter that aligns with your business requirements.

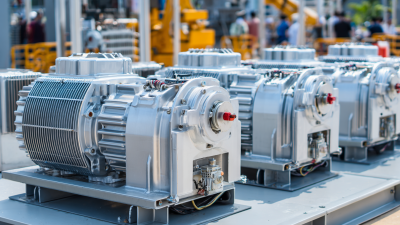

Understanding Solid State Phase Converters: The Basics Explained

Solid state phase converters are essential devices for businesses that rely on three-phase power for their operations. Unlike traditional rotary converters, solid state converters use semiconductor technology to convert single-phase power into three-phase power efficiently. According to a report by the U.S. Department of Energy, industrial applications utilizing phase converters can see energy efficiency improvements of up to 20% compared to older systems. This not only reduces operational costs but also enhances the overall performance of machinery.

When selecting a solid state phase converter, it's important to consider the power requirements of your equipment. A well-matched converter will ensure optimal performance and longevity of both the converter and your machinery. For instance, a typical industrial motor may require a converter that can handle a starting load up to 2 to 3 times its running current.

**Tip:** Always consult the manufacturer's specifications for both your motor and the converter to guarantee compatibility. Additionally, factor in the potential for future equipment upgrades, which may necessitate a more robust converter.

Another consideration is the environment in which the converter will operate. Solid state converters are often more compact and quieter than their rotary counterparts, making them suitable for facilities where noise and space are concerns.

**Tip:** Evaluate your facility's electrical infrastructure before making a purchase, ensuring that it can support the converter’s requirements without additional upgrades.

How to Choose the Right Solid State Phase Converter for Your Business Needs

| Converter Type | Power Rating (HP) | Phase Conversion Efficiency | Typical Applications | Cost Estimate |

|---|---|---|---|---|

| Solid State Converter | 5 HP | 95% | Machinery, Air Compressors | $500 - $700 |

| Digital Phase Converter | 10 HP | 97% | Industrial Equipment, CNC Machines | $800 - $1000 |

| Static Phase Converter | 3 HP | 90% | Pumps, Fans | $300 - $400 |

| Rotary Phase Converter | 15 HP | 92% | Large Motors, Manufacturing Equipment | $1200 - $1500 |

Key Factors to Consider When Selecting a Solid State Phase Converter

Choosing the right solid state phase converter for your business needs involves careful consideration of several key factors. First and foremost, evaluate the power requirements of your machinery. Understanding the voltage and current needs will ensure that the phase converter you select can adequately support your operations. A converter that supports your equipment without being oversized will save you on energy costs and enhance efficiency.

When selecting a solid state phase converter, it's crucial to consider the installation location. Adequate space, ventilation, and accessibility for maintenance should factor into your decision. Additionally, think about the future scalability of your operations. Opting for a converter that allows for system upgrades can save you time and costs down the road.

Tips: Always check for product reviews and testimonials from other businesses to gauge reliability and performance. It's also wise to consult with an expert or supplier who can provide insights tailored to your specific operational needs. Remember that investing in quality equipment today can prevent costly downtime and repairs in the future.

Types of Solid State Phase Converters and Their Applications

When selecting a solid-state phase converter, understanding the different types and their applications is crucial. The most common type is the static phase converter, which is designed to start three-phase motors and provide sufficient power for light loads. Static converters are ideal for small to medium-sized businesses that require moderate power for equipment like pumps and compressors. However, they may not be suitable for continuous use or for equipment that demands high starting torque.

Another popular option is the rotary phase converter, which can handle larger loads and is more versatile in applications. Rotary converters are well-suited for businesses that operate multiple three-phase machines simultaneously, as they create a three-phase power output by converting single-phase input. This type is especially beneficial for manufacturing and heavy-duty operations, where the reliability and capacity to handle fluctuating loads are necessary. Understanding these distinctions can help businesses choose the most appropriate converter that aligns with their operational needs and electrical infrastructure.

Solid State Phase Converters Types and Their Applications

Common Mistakes to Avoid When Choosing a Phase Converter

When selecting a solid state phase converter for your business, avoiding common pitfalls can significantly impact your operational efficiency. One frequent mistake is underestimating the power requirements of your equipment. Many businesses opt for a converter based solely on the nominal horsepower of their machinery without considering factors like startup loads, continuous usage, and peak demand. This can lead to performance issues, increased wear on the equipment, and even converter failure.

Another common error is neglecting to assess the compatibility of the converter with the specific electrical setup of your facility. Not all phase converters are designed to work seamlessly with every type of inverter or electrical system. Failing to ensure compatibility can result in operational disruptions and costly repairs. Additionally, businesses often overlook the importance of customer support and warranty offerings when making their choice, potentially leaving them stranded without assistance or recourse in case of issues. Taking time to research and understand these aspects will save time and money in the long run.

Maintenance Tips for Ensuring Longevity of Your Phase Converter

When investing in a solid state phase converter, it’s essential to not only select the right product but also to ensure its longevity through proper maintenance. According to a report by the Electrical Engineering Research Institute, routine maintenance can extend the lifespan of phase converters by up to 30%. Regular checks for overheating and loose connections can prevent operational failures and costly repairs.

One vital tip for maintaining your phase converter is to keep it clean and free from dust and debris. Accumulated dirt can lead to overheating, affecting performance. Additionally, monitoring the temperature of the device is crucial. The ideal operating temperature for most solid state phase converters is between 70°F and 100°F. Implementing a thermal management system can help maintain optimal temperatures and enhance efficiency.

Lastly, conduct periodic inspections and testing of the converter’s electrical components. The National Electrical Manufacturers Association suggests that even small discrepancies in voltage levels can lead to significant performance issues. By staying proactive with inspections, you can ensure that your phase converter continues to operate efficiently, ultimately supporting the productivity of your business.

Related Posts

-

Comprehensive Guide to Choosing the Right Voltage Frequency Converter for Optimal Performance

-

Ultimate Guide to Selecting the Right Power Converter for Optimal Efficiency

-

The Future of Solid State Frequency Converters Redefining Power Management

-

10 Reasons Why Solid State Frequency Converters Are Revolutionizing Global Supply Chain Efficiency

-

Exploring Unique Alternatives to Rotary Frequency Converters for Enhanced Efficiency

-

How to Choose the Right Single Phase to 3 Phase Converter for Your Business Needs